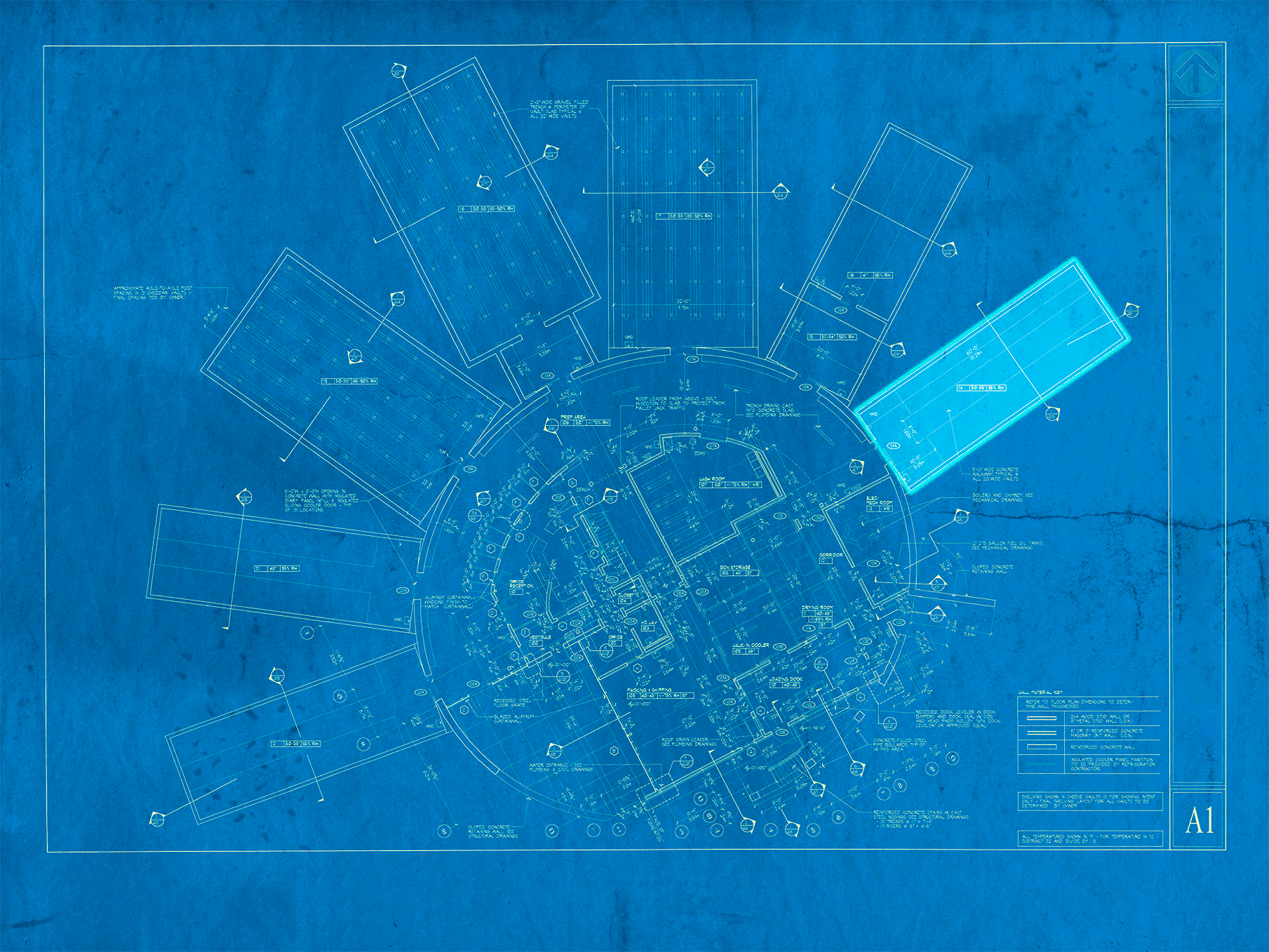

THE CELLARS AT

JASPER HILL FARM

Our Unique Complex of

Underground Vaults Designed

with Cheese in Mind

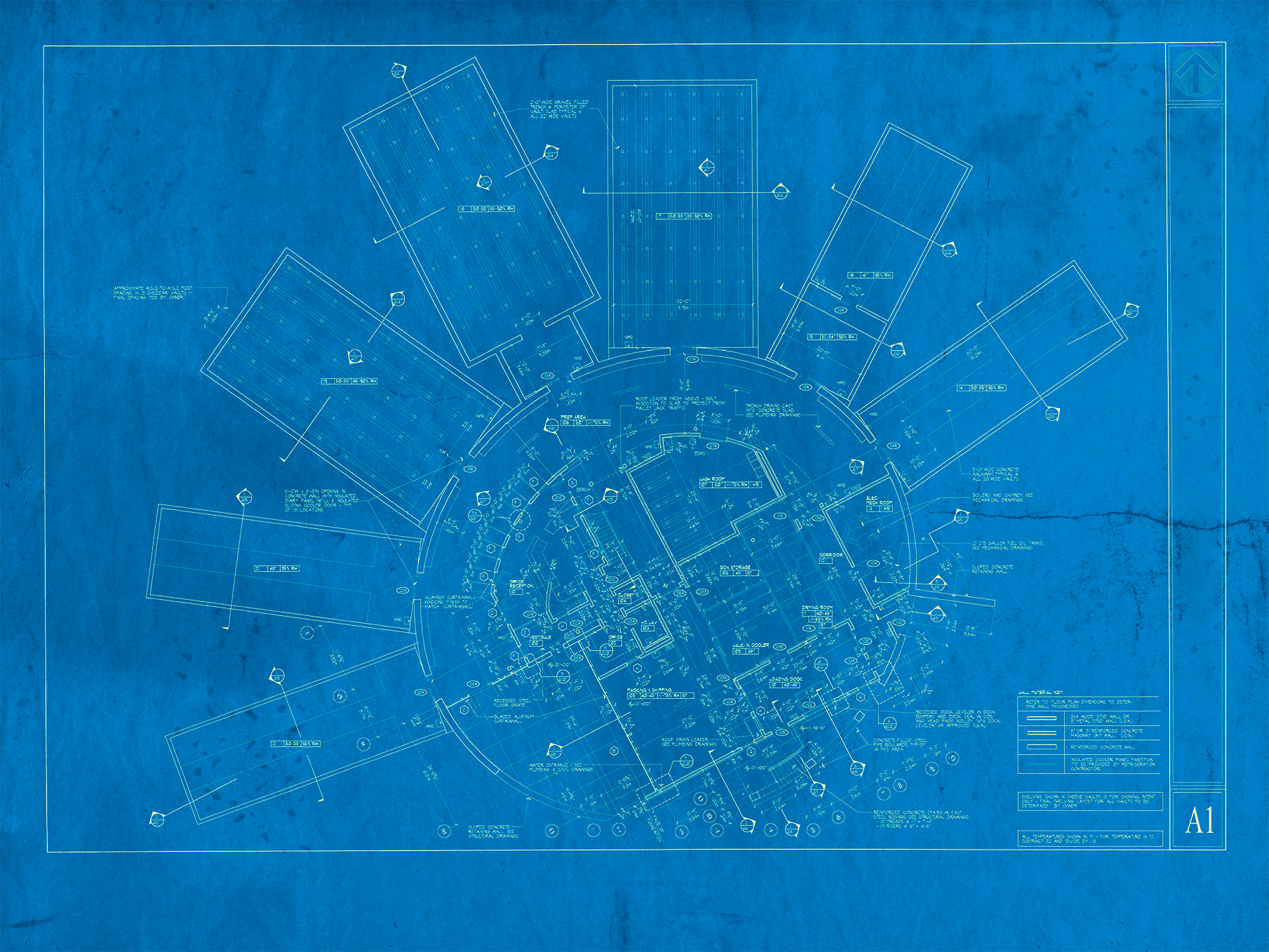

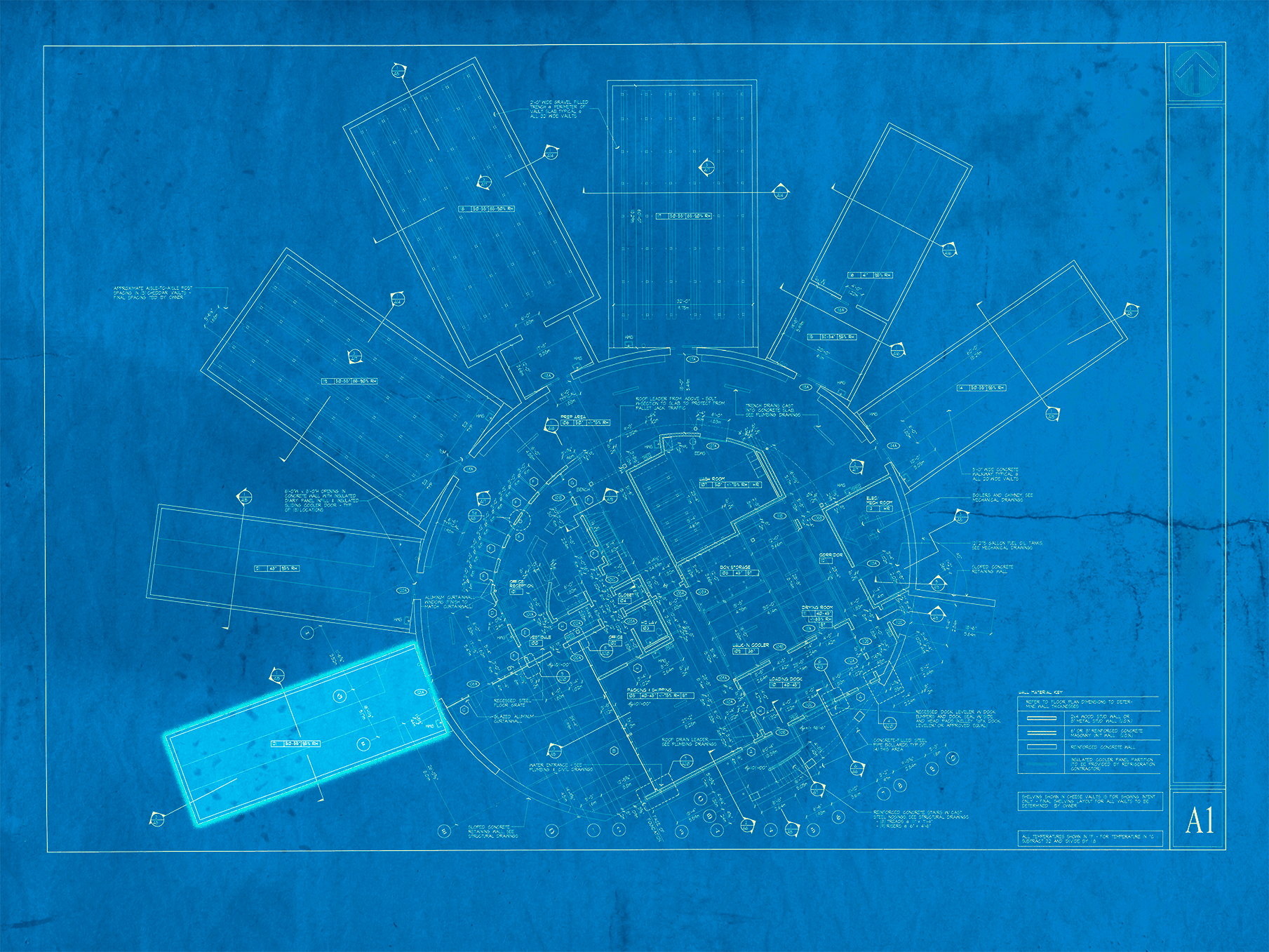

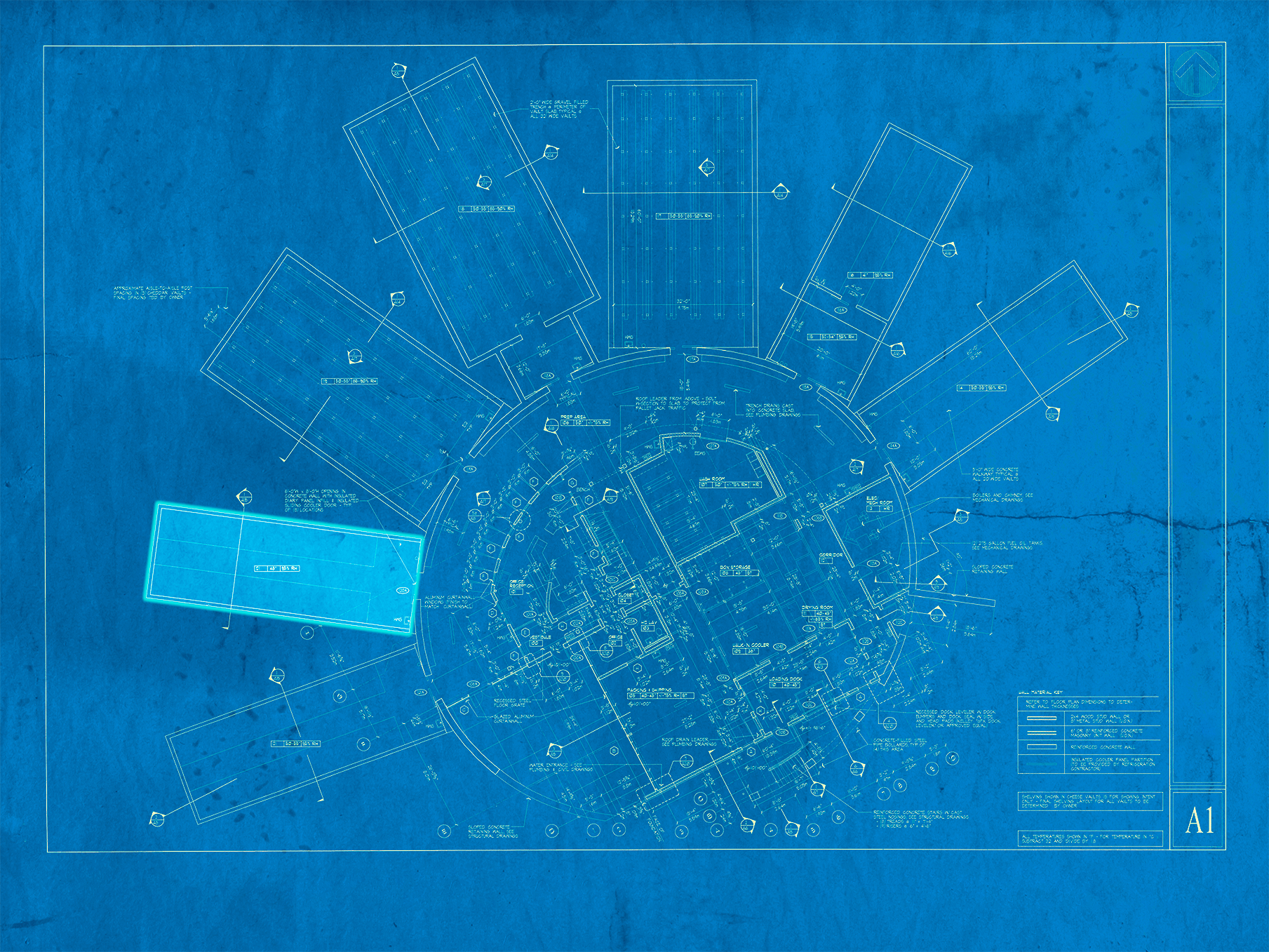

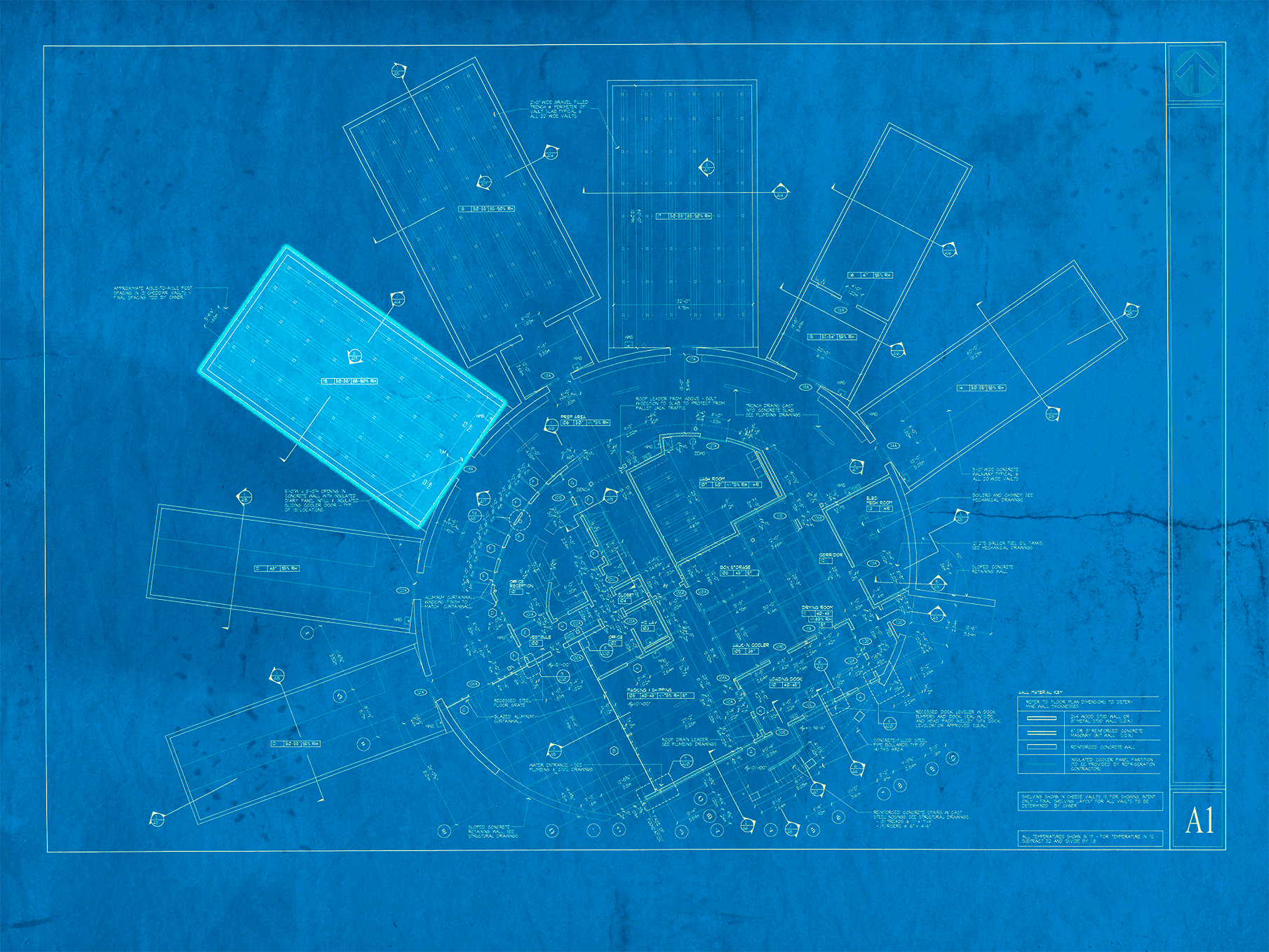

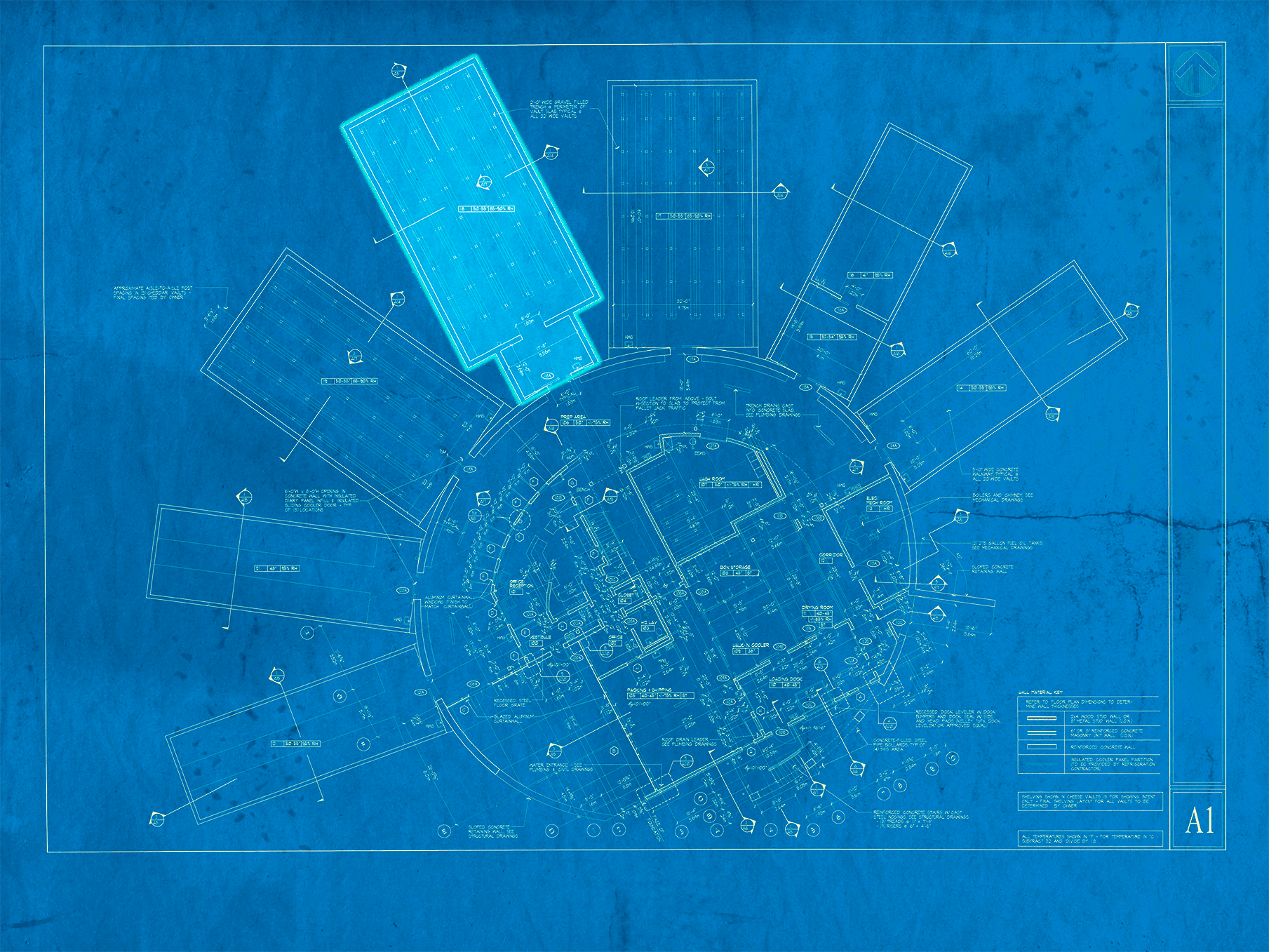

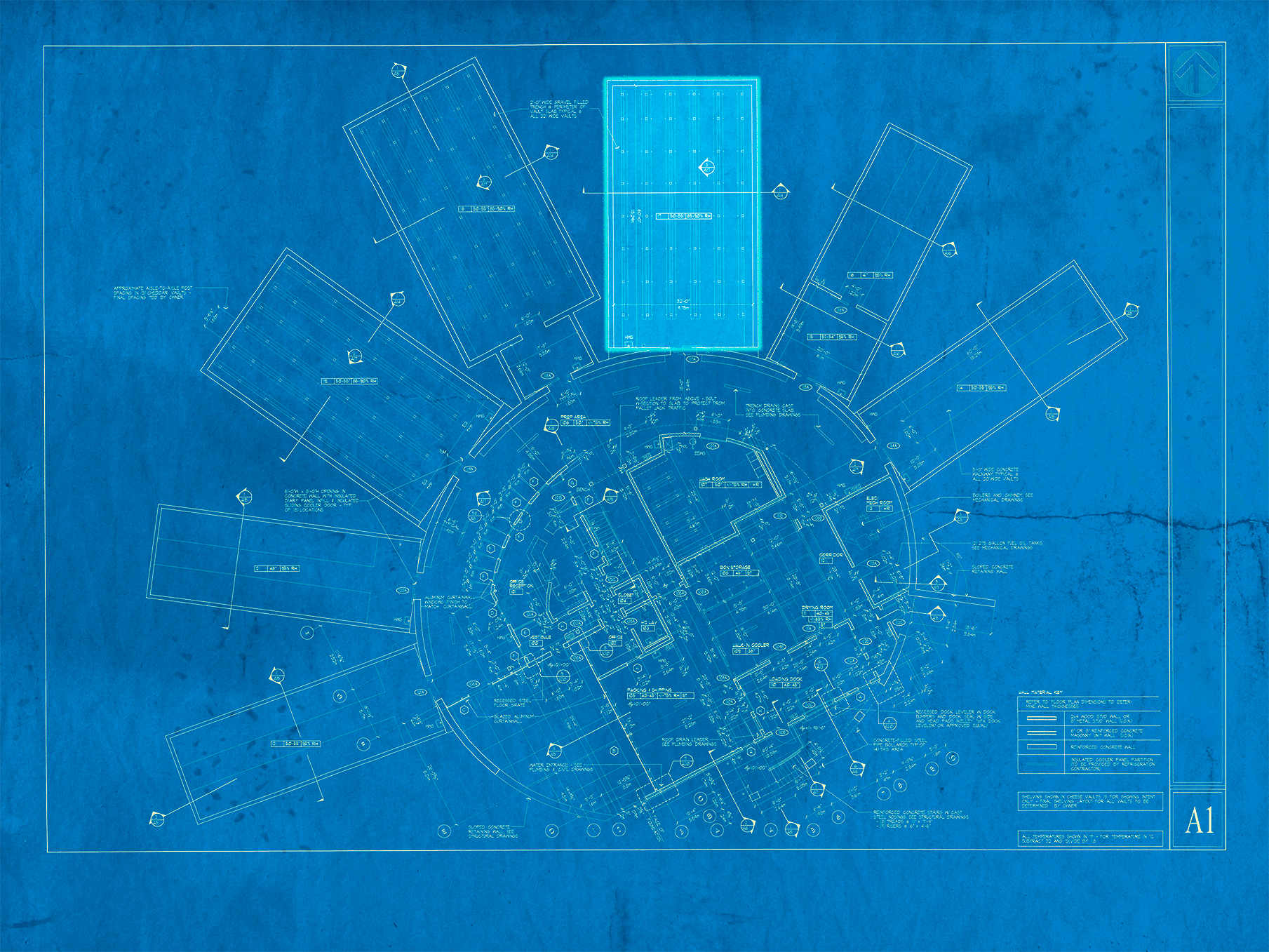

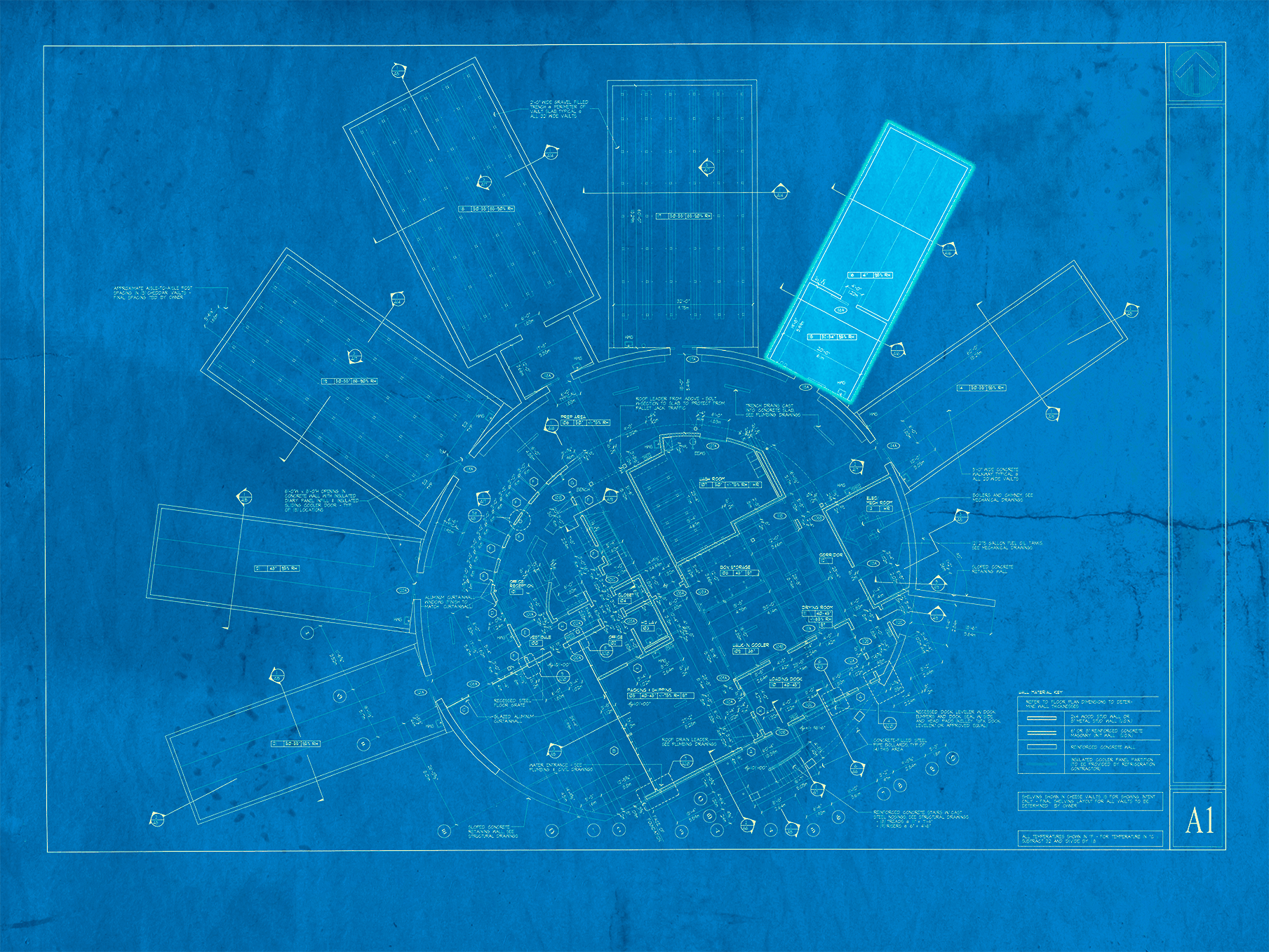

The Cellars at Jasper Hill Farm is an innovative 22,000-square-foot underground facility located in Greensboro, Vermont. The Cellars were constructed for the purpose of providing affinage, or aging expertise, as well as distribution and marketing services for local cheese makers. At the Cellars, we ripen cheese made by Jasper Hill Creameries as well as those made by several other producers. Each cheese in our collection is made from a single herd of cows. Fresh wheels are introduced to one of seven specially calibrated vaults, where they receive customized care until perfect ripeness.

EXPLORE THE ELLIPSE

The Ellipse is what we call the central ovoid structure from which our vaults radiate. The corridor that bends around the caves acts as the main thoroughfare in where our processing and packaging take place.

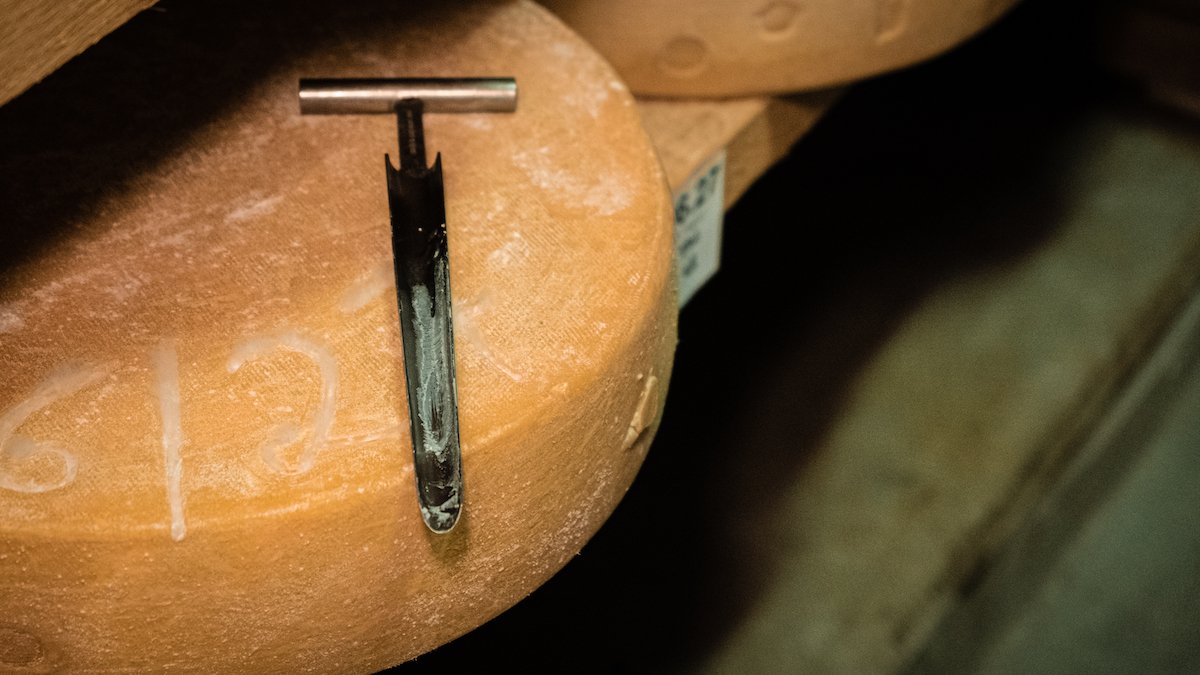

It is in our underground vaults that we perform all of our Affinage. Affinage is the French word for this traditional approach to cheese maturation; those who tend to the cheeses are called affineurs.

Affinage entails highly-focused, physical work including barking, washing, flipping, brushing, spiking, and salting. Our affineurs work hard to maintain the quality of our cheeses and monitor each of our seven climate-controlled vaults.

Our first vault is dedicated to bloomy rind cheeses. Harbison, Moses Sleeper, Sherry Gray, and Little Hosmer spend their time here.

This space has the highest air exchange of any of our vaults. The Penicilium varieties that constitute our bloomy rinds—namely penicillium camemberti—require plenty of oxygen to thrive.

Walking into the vault, one gets an immediate waft of pine aroma—a result of Harbison being freshly wrapped in spruce bark—mixed with the scent of white button mushrooms.

VAULT 1

Bloomy Rinds

Our second vault is dedicated to a process known as hastening. When young Whitney and Alpha Tolman arrive to the Cellars, they spend their first few weeks here growing the foundation for their rind.

The cool temperatures and higher humidity are ideal for cultivating brevibacterium linens—the microbe responsible for the pink-orange color of washed rind cheeses, as well as yeast.

These microbes come from a mother culture known as morge. This slurry contains strains of each microbe carried over from previous brines and is perfectly adapted to life in our vaults.

VAULT 2

Alpine Hastening

VAULT 3

Alpine

This vault has tall racks that tower over you filled to the brim with our mountain-style cheeses: Whitney, Alpha Tolman, and Calderwood, all inspired by mid-elevation cheeses from the Swiss & French Alps.

Vault 3 has an environment suited to the months-long affinage that it takes to produce these cheeses. The air is denser with smells typical of proteolysis—the breakdown of proteins.

Each wheel of cheese is brushed and turned regularly, some by hand, many by our faithful robot. Each batch is monitored by a vault specialist who decides if more or less brining will positively impact the cheese.

VAULT 4

Cheddar

We have two vaults dedicated to the ripening of Cheddar. Cabot Clothbound, our signature cave-aged Cheddar, is the primary occupant of this vault.

Cabot Creamery is one of our most instrumental collaborators; they approached us in 2003 asking us to grow a natural rind on their iconic Cheddar. In 2006, Cabot Clothbound took home the American Cheese Society Best of Show title. It has been a core part of our collection since.

Vault 4 is less humid with active air exchange. The cheeses lose moisture slowly at first, speeding up later on to produce a savory, friable texture.

VAULT 5

Cheddar

Our Cheddar program serves as the financial backbone, accruing value slowly over the course of 8-14 months. This slow affinage, however, means we need to dedicate a good deal of space to the cheese.

Vault 5 has given its name to another collaboration with Cabot: blocks of alpine-cultured cheddar are made at Cabot creamery and shipped to our cellars for rind development. The result is the nutty & meltable Vault 5.

As with Vault 4, the environment is a little drier with a high degree of air exchange to offset heat produced by enzymatic reactions during aging.

VAULT 6

Washed Rinds

Washed Rind cheeses like Willoughby, Eligo, and Oma are the most temperature-sensitive of all the styles we produce. This vault is high-moisture with average temperatures in the mid 40º Fahrenheit.

Larger formats like Eligo and Oma must be washed by hand. Affinieurs use bristle brushes to apply brine and lightly scarify the cheeses’ rind.

Willoughby, however, has a dedicated device known affectionately as Gruffy that saves our staff many joint aches. This machine brines and brushes young wheels of Willoughby and saves our affineurs time.

VAULT 7

Natural Rinds

While all of our rinds are “natural,” we call the cheeses in this vault because they receive the least active intervention.

Bayley Hazen Blue is the signature cheese of Vault 7. Here, young wheels are salted and spiked before transitioning to 60 days of development on pine boards. We choose to age these cheeses on wood because of its ability to moderate oxygen and moisture exchange on the points where it contacts the cheese.

Vault 7 is typically high humidity with one of the highest degrees of air exchange, though can vary depending on how its residents are evolving.